In the fast-paced world of fleet management, every detail counts—from fuel efficiency to driver safety, and even the weight of each vehicle on the road. Overloaded trucks aren’t just a minor inconvenience; they’re a major risk to road safety, compliance with regulations, and a company’s bottom line. For years, fixed axle weighing stations were the go-to solution, but they came with their own set of challenges: long wait times, limited accessibility, and high installation costs. Enter portable axle weighing systems—a game-changing technology that’s revolutionizing how fleet managers monitor and maintain vehicle weight. In this blog, we’ll break down how these systems work, why they’re a must-have for modern fleet operations, and how they can boost your SEO efforts by addressing key industry pain points.

What Are Portable Axle Weighing Systems?

Before diving into the mechanics, let’s clarify what portable axle weighing systems are. Unlike fixed weighbridges that are permanently installed at specific locations (like truck stops or distribution centers), portable systems are lightweight, mobile devices designed to measure the weight of individual axles (and sometimes the entire vehicle) anywhere, anytime. They’re typically compact enough to fit in a truck’s cargo area, making them ideal for on-site checks at warehouses, construction sites, or even remote delivery locations.

Key Components of Portable Axle Weighing Systems

To understand how these systems work, it’s essential to know their core components. Most portable axle scales consist of:

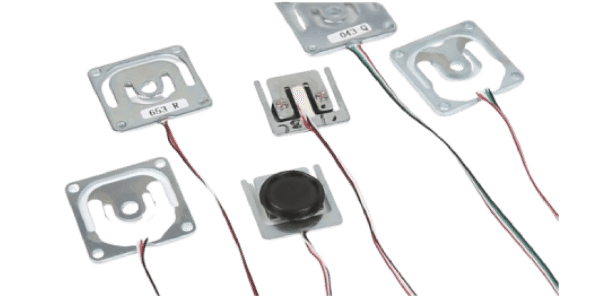

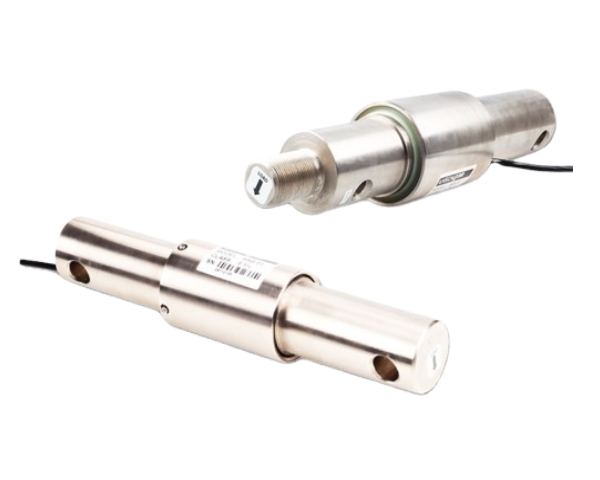

1.Load Cells: These are the heart of the system. Load cells are sensors that convert mechanical force (the weight of the axle pressing down) into an electrical signal. High-quality load cells are calibrated to detect even small weight variations, ensuring accuracy.

2.Weighing Pads: These are the physical surfaces where the vehicle’s axles rest. Made from durable materials like steel or aluminum, they’re designed to withstand heavy loads (often up to 30,000 pounds per pad) and harsh weather conditions.

3.Digital Indicator: This is the user interface. It displays the weight readings from the load cells, often with features like data storage, USB connectivity, and wireless transmission. Some indicators even have touchscreens for easy operation.

4.Power Source: Portable systems are usually battery-powered, with rechargeable lithium-ion batteries that last for hours (or even days) on a single charge. This makes them perfect for off-grid use.

5.Software Integration: Many modern systems come with companion apps or cloud-based software that lets fleet managers store, analyze, and share weight data in real time. This is a game-changer for data-driven decision-making.

How Do Portable Axle Weighing Systems Work?

The operation of portable axle scales is surprisingly straightforward, but it relies on precise engineering. Here’s a step-by-step breakdown of the process:

Step 1: Setup and Calibration

First, the user places the weighing pads on a flat, stable surface (like asphalt or concrete). It’s crucial to ensure the pads are level—even a small incline can affect accuracy. Most systems come with a level indicator to help with this. Next, the load cells are calibrated to account for any environmental factors (like temperature or humidity) that might impact readings. Calibration is usually done using a known weight (like a test block) to ensure the system is accurate.

Step 2: Vehicle Positioning

The vehicle drives onto the weighing pads, one axle at a time. For example, if a truck has three axles, the driver will position the first axle on the pad, wait for the reading to stabilize, then move the second axle onto the pad, and so on. Some systems use two pads (one for each side of the axle) to measure the weight distribution across the vehicle, which is critical for safety (uneven weight can cause rollovers).

Step 3: Data Collection and Processing

As the axle rests on the pad, the load cells compress under the weight. This compression generates an electrical signal that’s sent to the digital indicator. The indicator converts the signal into a readable weight measurement (usually in pounds or kilograms). Advanced systems can also calculate the total vehicle weight by summing the axle weights.

Step 4: Data Storage and Analysis

Once the readings are taken, the data can be stored locally on the indicator or transmitted wirelessly to a smartphone, tablet, or cloud server. Fleet managers can then access this data to:

-

Verify that the vehicle is within legal weight limits.

-

Identify overloaded axles that need adjustment (like redistributing cargo).

-

Track weight trends over time to optimize loading processes.

Why Portable Axle Weighing Systems Are Essential for Fleet Management

Now that we know how they work, let’s explore the benefits that make portable axle scales a must-have for fleet managers. These benefits directly address common pain points in the industry, making them a valuable addition to any operation.

1. Compliance with Weight Regulations

One of the biggest challenges for fleet managers is staying compliant with local, state, and federal weight limits. Overloaded trucks can result in hefty fines (sometimes thousands of dollars per violation), license suspensions, or even impoundment. Portable axle scales let you conduct on-the-spot checks before a vehicle hits the road, ensuring you never run afoul of regulations. For example, in the U.S., the Federal Motor Carrier Safety Administration (FMCSA) enforces strict axle weight limits (e.g., 20,000 pounds for a single axle, 34,000 pounds for a tandem axle). With a portable system, you can verify compliance in minutes, avoiding costly penalties.

2. Improved Safety

Overloaded vehicles are a major safety hazard. They have longer stopping distances, reduced maneuverability, and an increased risk of tire blowouts or rollovers. According to the FMCSA, overloaded trucks are involved in a significant number of fatal crashes each year. Portable axle scales help you prevent overloading, protecting your drivers, other road users, and your company’s reputation. By ensuring each axle is within its weight limit, you reduce the risk of accidents and create a safer work environment.

3. Cost Savings

Fixed weighbridges can cost tens of thousands of dollars to install and maintain. Portable systems, on the other hand, are much more affordable—with prices ranging from $2,000 to $10,000, depending on features. But the savings don’t stop there:

-

Reduced Fines: As mentioned, avoiding overloading fines can save you thousands annually.

-

Lower Maintenance Costs: Overloaded axles put extra stress on tires, brakes, and suspension systems, leading to frequent repairs. By keeping weights in check, you extend the lifespan of these components.

-

Fuel Efficiency: Overloaded trucks burn more fuel. The U.S. Department of Energy estimates that every 10% increase in vehicle weight reduces fuel efficiency by 5-6%. Portable scales help you optimize load distribution, cutting fuel costs.

4. Increased Operational Efficiency

Fixed weigh stations often have long queues, especially during peak hours. This can delay deliveries, disrupt schedules, and frustrate drivers. Portable axle scales eliminate this problem by letting you weigh vehicles at your convenience—whether it’s at your warehouse before departure or at a construction site mid-project. No more waiting in line; you can conduct checks in minutes, keeping your fleet moving. For example, a construction company might use a portable scale to verify that a dump truck isn’t overloaded before it transports gravel to a remote job site, saving time and ensuring compliance.

5. Data-Driven Decision Making

Modern portable systems come with software that lets you collect and analyze weight data over time. This data can reveal valuable insights, like:

-

Which routes have the most overloading issues.

-

How load distribution affects fuel efficiency.

-

Which drivers consistently follow weight guidelines.

By leveraging this data, you can make informed decisions to optimize your fleet operations. For example, if you notice that a particular driver often overloads their truck, you can provide additional training. If data shows that certain routes have stricter weight enforcement, you can adjust your loading process for those trips.

Choosing the Right Portable Axle Weighing System

Not all portable axle scales are created equal. When selecting a system for your fleet, consider the following factors:

Accuracy

Look for systems with a high accuracy rating (e.g., ±0.1% of the applied load). This ensures that your weight readings are reliable and compliant with regulations.

Durability

Since portable scales are used in harsh environments, they need to be tough. Choose systems with weather-resistant components (like stainless steel load cells) and a high weight capacity.

Portability

The whole point of a portable system is mobility. Look for lightweight models (under 50 pounds per pad) that are easy to transport and set up.

Software Features

If data analysis is important to you, opt for a system with cloud-based software or a mobile app. This lets you access and share data in real time.

Customer Support

Finally, choose a manufacturer with excellent customer support. You’ll want help with calibration, troubleshooting, and software updates.

Conclusion

Portable axle weighing systems are more than just a tool—they’re a strategic investment that can transform your fleet operations. By understanding how they work and leveraging their benefits (compliance, safety, cost savings, efficiency, and data insights), you can take your fleet management to the next level. And from an SEO perspective, creating content around these systems lets you target key keywords, address industry pain points, and build authority in your niche.

Whether you’re a small business with a handful of trucks or a large fleet operator managing hundreds of vehicles, portable axle scales are a must-have. They’re convenient, accurate, and cost-effective—everything you need to keep your fleet running smoothly and safely. So why wait? Invest in a portable axle weighing system today and see the difference it makes for your business.

Remember, in the world of fleet management, knowledge is power—and portable axle scales give you the power to make informed decisions that drive success.

Disclaimer: The information in this blog is for educational purposes only. Always consult with a professional before implementing new technology in your fleet operations.

HOT keyword: